Manufacturing Trends in 2020 and Beyond!

For the last four years, we’ve been writing articles about the new industrial revolution that was underway and how and why manufacturers should get involved. These articles were focused on Supply Chain collaboration, Shop Floor automation, Change Management, Sales and Operations planning, Lean Manufacturing and the need to have a fully optimized ERP system at the foundation of all strategies and plans.

COVID-19 introduced a new challenge to the world and to all manufacturers. One that required manufacturers to take a closer look at Automation, Supply Chain Collaboration, sales and marketing channels, Digital Analytics, ERP systems and of course the all-important Change Management. While manufacturing companies had no control over COVID-19 occurring, they do have a choice when it comes to how they address the challenges it has created.

We’d like to share our insights, based on experience, on the process manufacturers are following to realize their full potential in order to maximize profit, particularly during these challenging times.

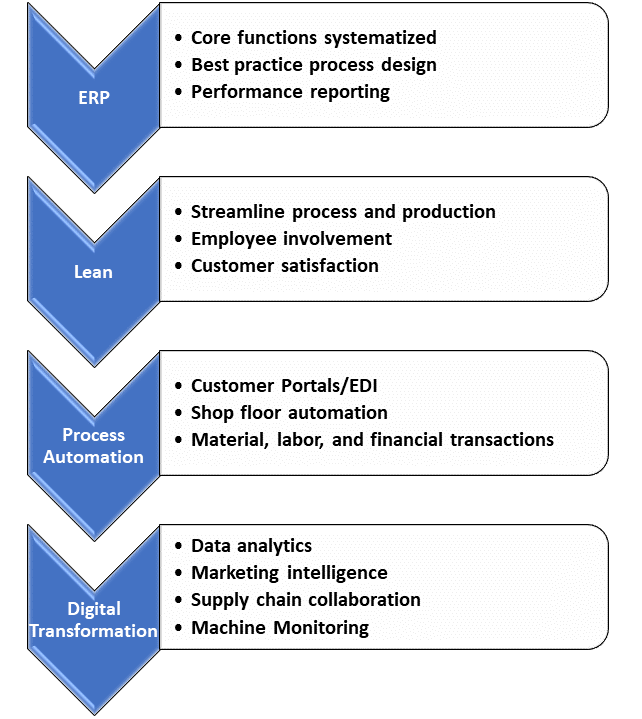

At the core of all successful manufacturers you’ll find a fully optimized ERP system built on best practice processes and well-defined performance data. Analytics will allow you to easily monitor key performance indicators and your employee base will be fully trained and engaged. This platform serves as the foundation on which the business can be built and scaled in growth situations. If your ERP is not fully optimized or your employees are not adequately trained and engaged – this is your starting point!

With an optimized ERP system in place, the transition to Lean becomes easier. The focus on further eliminating waste, employee engagement and streamlining production will help you identify areas of improvement that will have a positive impact on profit. Change Management becomes a major focus at this point and should never be left to inexperienced individuals. Change Management requires a very focused, deliberate set of actions that is best delivered or directed by an experienced individual.

An effective Lean program will lead to opportunities for process automation to increase efficiency and productivity. Waste elimination is a critical driving point on the journey to achieve operational excellence.

Now, your company has the foundation, discipline and much needed culture to advance operations into the digital transformation era. There is strong agreement that digital transformation is critical for manufacturers to remain relevant, competitive and viable. But success requires achievement in establishing the foundation, changing the culture and true acceptance that digital transformation is not a technical project. It is a project requiring active top senior management buy-in and enterprise-wide participation.

Where in this journey is your company today? What is your strategy and plan to advance?

Based on manufacturers that we have personal experience with, we can say for certain that as we move through the next decade manufacturers across the world are taking these very distinct and well-defined actions to win business, grow their company and become highly profitable. To remain competitive, profitable and viable, you will need to stay ahead of the competition.

Contact us to learn how we can help you plan your manufacturing strategy as we continue to navigate the new industrial revolution.

Authors:

Michael Canty, Executive Vice President

Katie Farrand, Continuous Improvement Manager