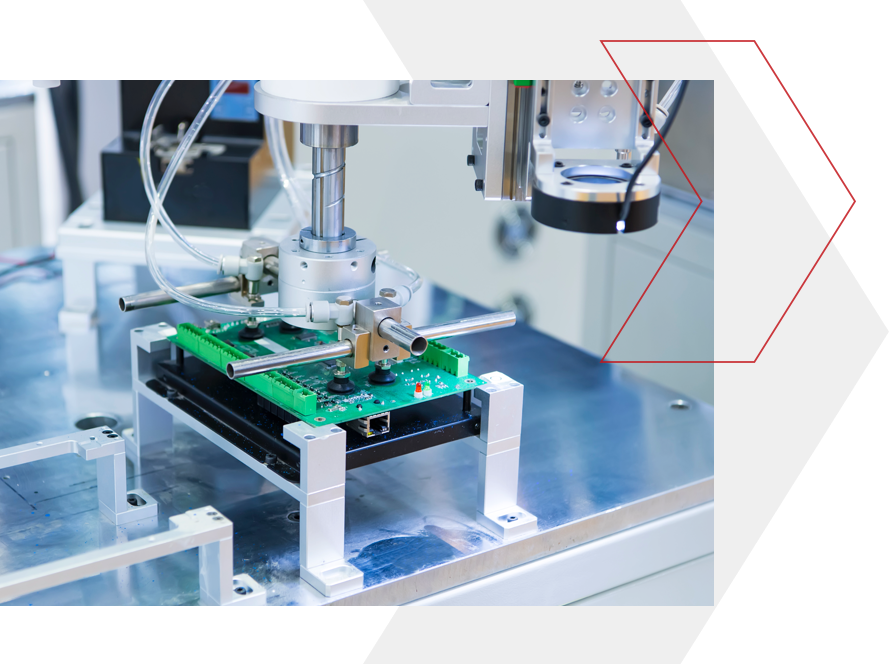

Maximize innovation with ERP for Electronics Manufacturing.

High-tech customer expectations, combined with the quick pace of technological advancement, put tremendous pressure on your already complex product cycle to get innovative products to market as quickly as possible. An ERP for electronics manufacturing can boost efficiency and productivity while increasing growth and productivity.