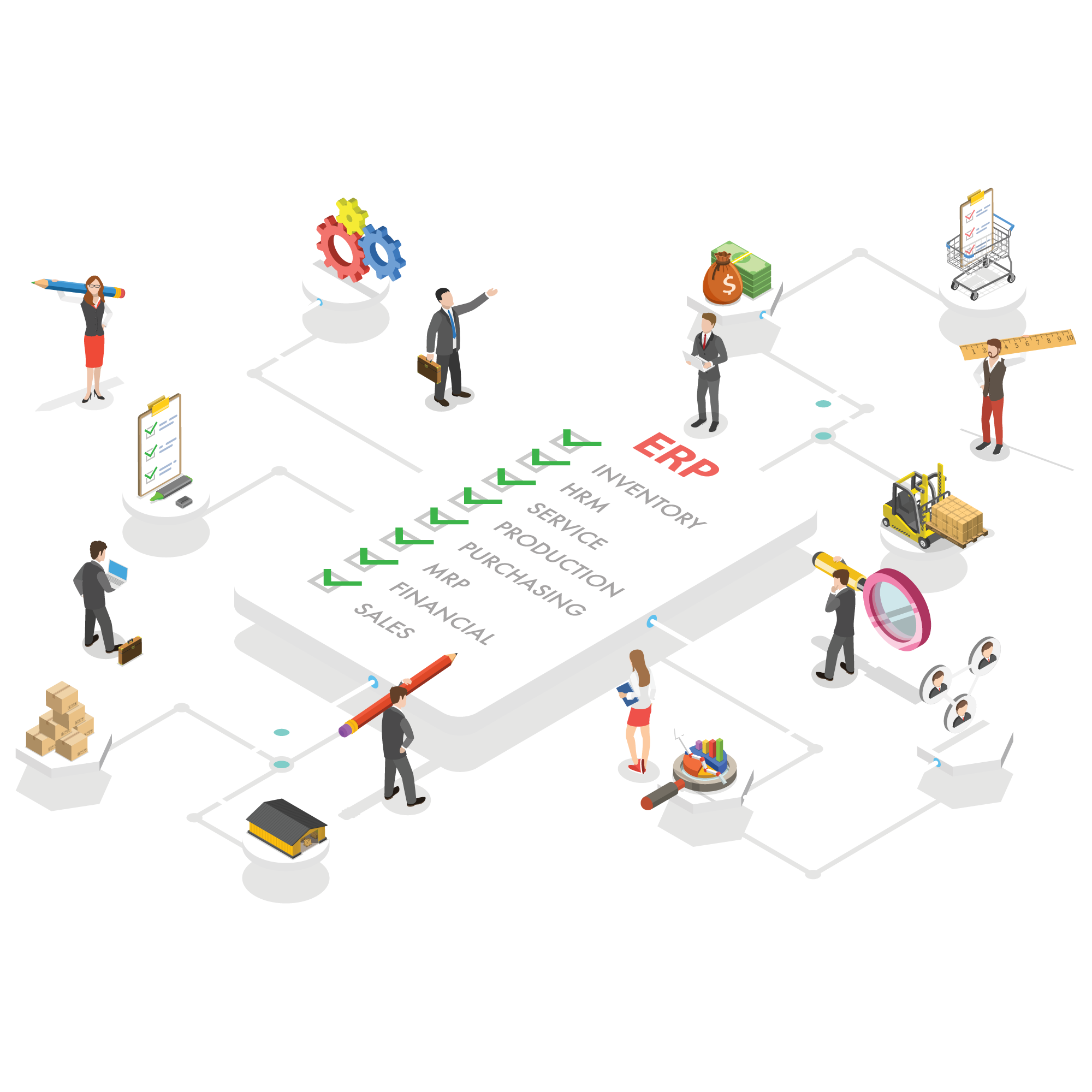

Consulting for ERP Solutions and Beyond

Our ERP offerings include a range of top-shelf solutions from the world’s best ERP software companies along with a broad suite of integrations and extensions to align with our clients’ digital transformation and business growth goals.

Explore Our Center of Excellence for Dynamic Optimization

At WM Synergy, we help you make the most of your investment in ERP Technology & Resources

Take a free assessment and discover your prime areas of opportunity in:

Lean Manufacturing, Supply Chain Management, Materials/Inventory, and Production Management

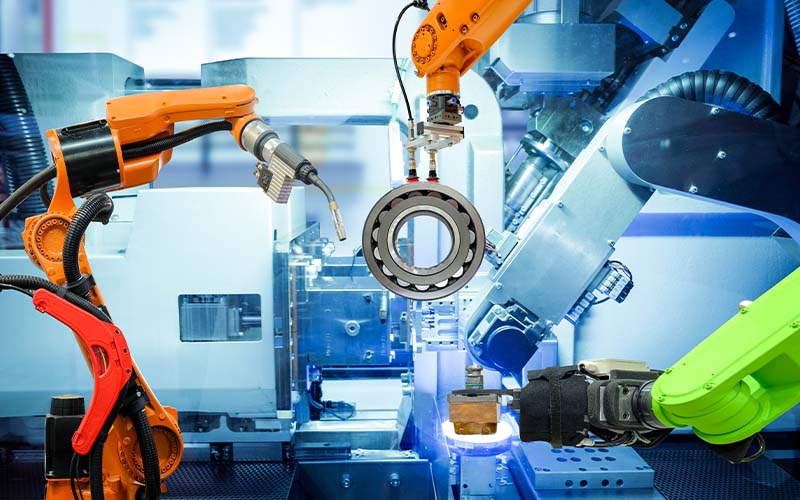

Our Innovation Center is the Engine for Customer-Driven Development

We continually invest in Research & Development to ensure today’s ERP software meets your needs. The best ideas come from our customers, staff, and partners. We are dedicated to tracking every idea and pursuing the ones that will have the biggest impact for our customers. From software platform integrations to shop floor automations to business process improvements, our Innovation Center team looks forward to creating future thinking solutions.

We understand the power of APIs (Application Programming Interface) as the method of connecting modern software together to match any business process. Our approach allows our team to move quickly from idea to proof-of-concept and ultimately, a working solution.

As part of our Zoho CRM implementation, we had the pleasure of working with the Innovation Center team. They have been very professional in their engagement with us on the project. They add not only the technical expertise for our integration from Zoho CRM to Infor VISUAL but have also guided us in best practices for properly leveraging the system for our unique business needs. The team has recommended various strategies and techniques as part of the integration that has allowed us to think beyond a simple integration and to really embrace the power of the tools he is providing.

Learn about WM Synergy & Meet Our Team

Our Mission: To help manufacturers and distributors realize their powerful potential through continuous improvement, relentless resourcefulness, and collaborative ingenuity that recognizes no limits.