Additive Manufacturing – The Next Industrial Revolution

Written by Robert Anand

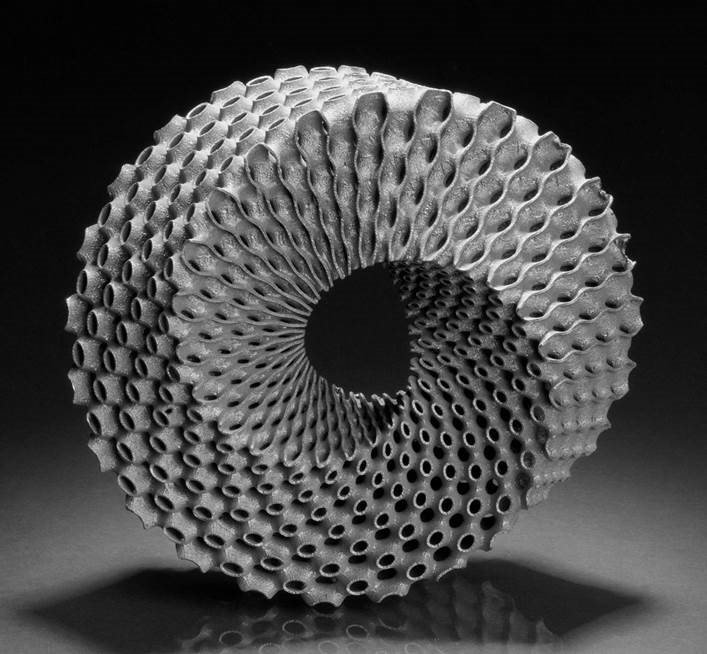

Additive Manufacturing (AM) is the name to describe the technologies that build 3D objects by the accumulation (layer-upon-layer) of material, whether the material is plastic, metal, concrete or even human tissue.

Common to AM technologies is the use of a computer, CAD software, machine equipment and layering material. Once a CAD MODEL is produced, the AM equipment uses data from the CAD file to lay down or add successive layers of liquid, powder, sheet, or other material, in a layer-upon-layer fashion to fabricate a 3D object.

The term AM encompasses many technologies including 3D Printing, Rapid Prototyping (RP), Direct Digital Manufacturing (DDM), layered manufacturing and additive fabrication.

Examples of Additive Manufacturing include:

FDM

Process oriented involving use of thermoplastic (polymer that changes to a liquid upon the application of heat and solidifies to a solid when cooled) materials injected through indexing nozzles onto a platform. The nozzles trace the cross-section pattern for each particular layer with the thermoplastic material hardening prior to the application of the next layer. The process repeats until the build or model is completed and fascinating to watch. Specialized material may be need to add support to some model features. Similar to SLA, the models can be machined or used as patterns. Very easy-to-use and cool.

MJM

Multi-Jet Modeling is similar to an inkjet printer in that a head, capable of shuttling back and forth (3 dimensions-x, y, z)) incorporates hundreds of small jets to apply a layer of thermopolymer material, layer-by-layer.

SLA

Stereolithography is a technology utilizing lasers to cure layer-upon-layer of photopolymer resin (polymer that changes properties when exposed to light). The build occurs in a pool of resin. A laser beam, directed into the pool of resin, traces the cross-section pattern of the model for that particular layer and cures it. During the build cycle, the platform on which the build is repositioned, lowering by a single layer thickness. The process repeats until the build or model is completed and fascinating to watch. Specialized material may be needed to add support to some model features. Models can be machined and used as patterns for injection molding, thermoforming or other casting processes.

SLS

Somewhat like SLA technology Selective Laser Sintering (SLS) utilizes a high powered laser to fuse small particles of plastic, metal, ceramic or glass. During the build cycle, the platform on which the build is repositioned, lowering by a single layer thickness. The process repeats until the build or model is completed. Unlike SLA technology, support material is not needed as the build is supported by unsintered material.

LMD

Laser deposition welding, also called laser metal deposition (LMD), is a generative laser procedure in which metal is applied on existing tools and components in layers. The laser generates a molten bath on the existing surface into which one or more metal powders is sprayed through a nozzle. The powder then melts and bonds with the base material. Bit by bit, a new material layer develops. Using LMD, certain properties of parts can be targeted for improvement by systematically refining or combining materials. For example you can give a softer metal a hard, high-quality surface; combine a thermally insulating material with a conductive layer; or coat metal with materials that resist high temperatures, salt water, or chemicals. Laser deposition will not only lengthen the life components, it can also significantly reduce the overall manufacturing costs.

Once confined to manufacturing labs and research institutions, Additive Manufacturing has taken hold in industry. GE expects to manufacture over 100,000 parts using this technology by 2020.

Have you introduced any additive manufacturing processes in your shop? We’d love to hear about it! Contact us to tell us your story!